|

Shanghai Golden-hammer forgings co.,ltd

|

Forged Trunnion 20 21

| Price: | 100.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

Founded in 2000, JC forging is a professional manufacturer of precision forging parts.

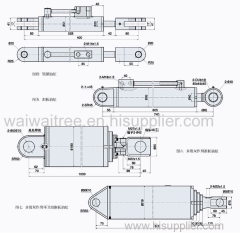

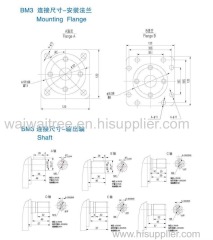

Founded in 2000, JC forging is a forged components manufacturer of forged metal products. The company's main product is die mold forging parts, including but not limited to forged hydraulic cylinder bottoms, forged hydraulic cylinder end cap, forged hydraulic cylinder earring, and forged clevis, forged trunnions and other custom metal forgings.

Product: forged trunnion

Application: hydraulic cylinder, truck

Place of origin: Hebei, China (Mainland)

Material: C45, 20, ASTM A216 70-36 grade WCB

Process: die mold forged, forging + CNC machining,

Surface treatment: anti-rust oil or painting

Surface roughness: 12.5Ra

Weight: 0.5-50kg

Sample lead-time: 3-8 weeks

Heat treatment: normalizing, quenching, tempering and annealing

Forged ak trunnion is a cylindrical protrusion used as a mounting or pivoting point. First associated with cannons, they are an important military development. Alternatively, a forged trunnion is a shaft that positions and supports a tilting plate. This is a misnomer, as in reality it is a cradle for the true forged trunnion.

Product Description of forged trunnion ak

Forged Trunnion Description

Customized drawings are accepted.

Standards: ASTM, AISI, ANSI, AWS, ASME, AB, SAE, API, BS, CAS, JIS and DIN

Packing: seaworthy packing or as per clients' requirements

Competitive Advantages of Forged Trunnion:

1. Forged in 1000°C, one or two step forging create accurate profile.

2. CNC machining guarantee the dimensions.

3. Big customer long-term corporation experience

4. Strictly quality control and timely delivery guaranteed

5. Trial or small orders are accepted

The forged trunnion used on different type of cylinders, strong and durable.

The precision forging process of forged trunnion can guarantee the material without defect inside the parts.

We can provide machined forged trunnion according to customer's drawings.

Forging is a process method that uses forging machinery to exert pressure on metal blanks, causing them to create plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. By forging can eliminate the metal in the smelting process of the casting state loose and other defects, optimize the microstructure, and because of the preservation of complete metal streamlined, forging mechanical properties are generally better than the same material castings